Reactor Powder Feeding System – (Bag Unloading Station) in Paint Industry

A bag unloading station is a designated area or system where bags, typically in industrial settings, are unloaded from trucks, conveyor belts, or other transport mechanisms. These stations often include equipment like conveyors, hoppers, or chutes to facilitate the unloading process efficiently. The material is received in the industries in various sizes of bags, like small and big jumbo size bags.

Stratgem offers best solutions related to industrial small and jumbo bag Unloading Stations for the Industries like Food, Chemicals, Paints and pigments and many more.

Raw materials required for Paint and pigment industries are in powdered form and generally brought into the plants in small (25 kg or 50 kg) and big bags (1 MT). It is required to install efficient powder handling and storage systems for these powders. (MT-Metric Tons).

A major paint manufacturer approached us to automate their existing material feeding system into the reactors. The different types of material being fed to reactors are LAPOX P-5, Maletic Anhydride, Benzoic Acid, NPG-90 Glycol, Pentaerythritol tech, paraformaldehyde, and bisphenol.

Most of these powders are flammable, carcinogenic, and possess many hazards if exposed to humans.

The Current feeding process is manual, which is has many issues such as material spillage, waste, dusting, and exposure of harmful chemical powders to workers.

StratGem's Reactor Powder Feeding System

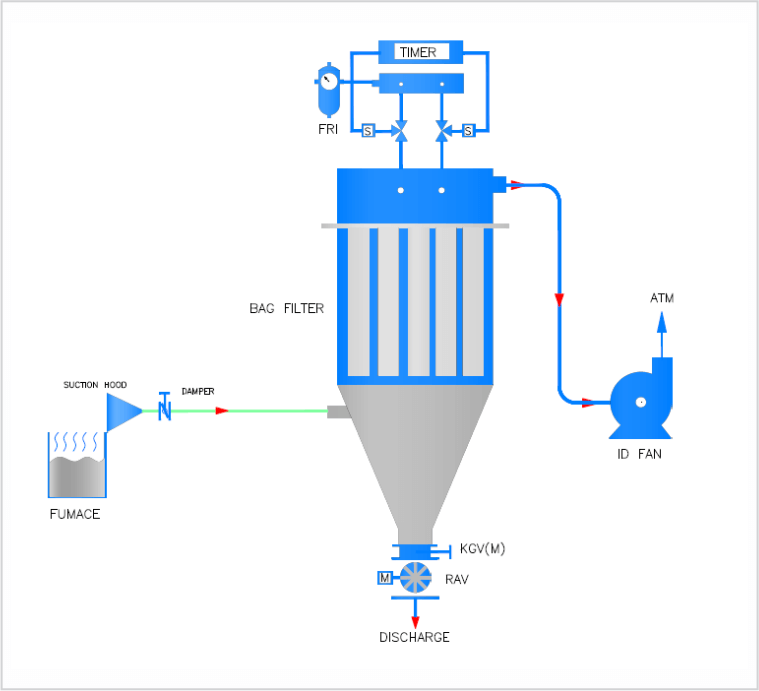

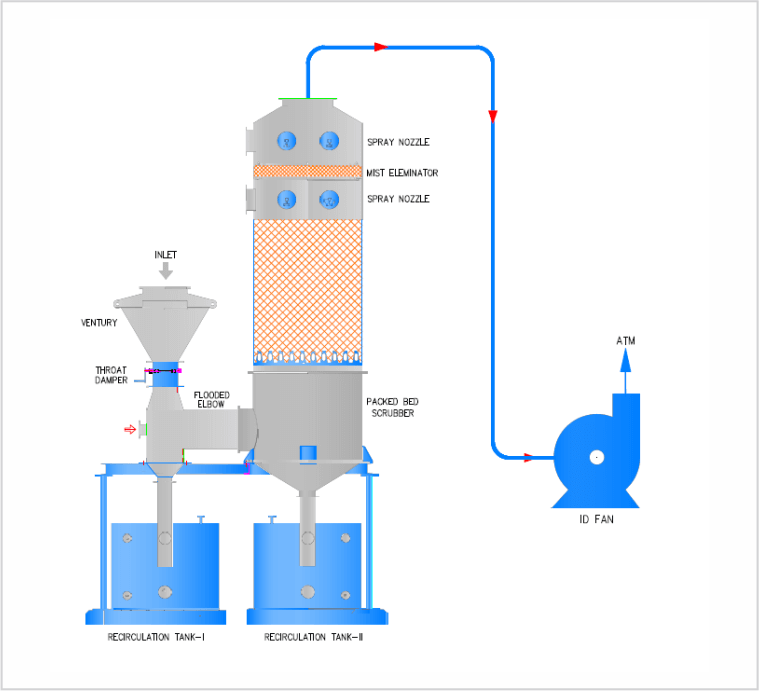

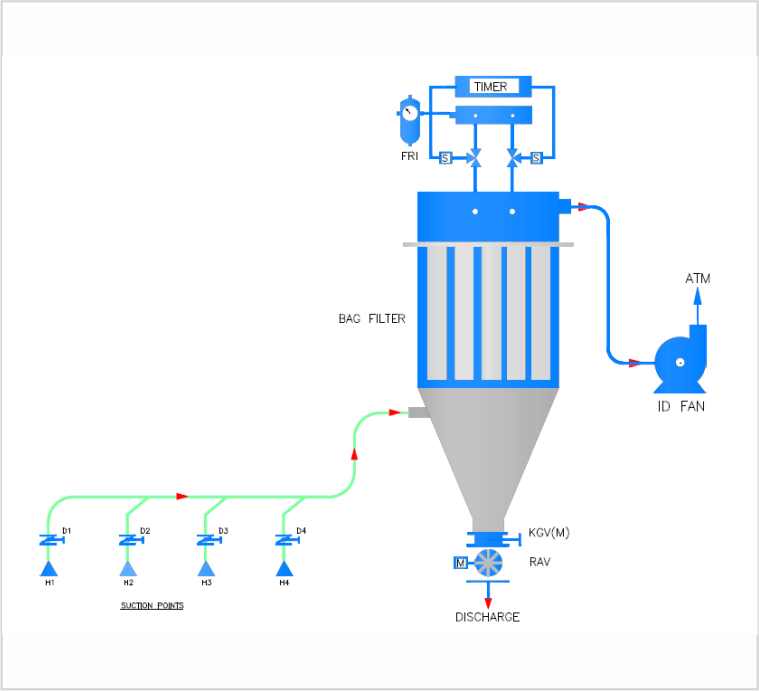

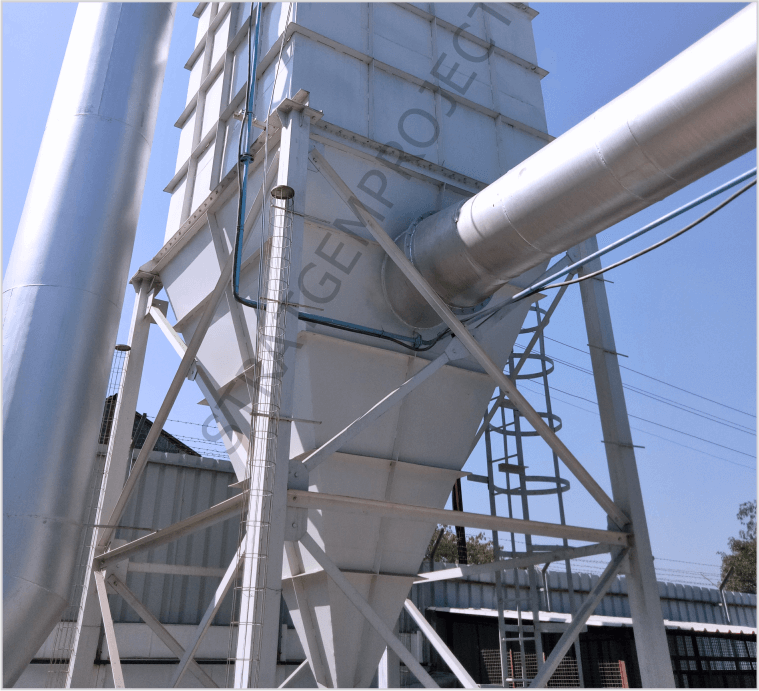

Our system is designed with an unloading station for small bags weighing 25 to 50 kg. Vent filter provided on the unloading station ensures a dust-free environment by capturing the dust generated during the unloading process to further enhance workplace cleanliness.

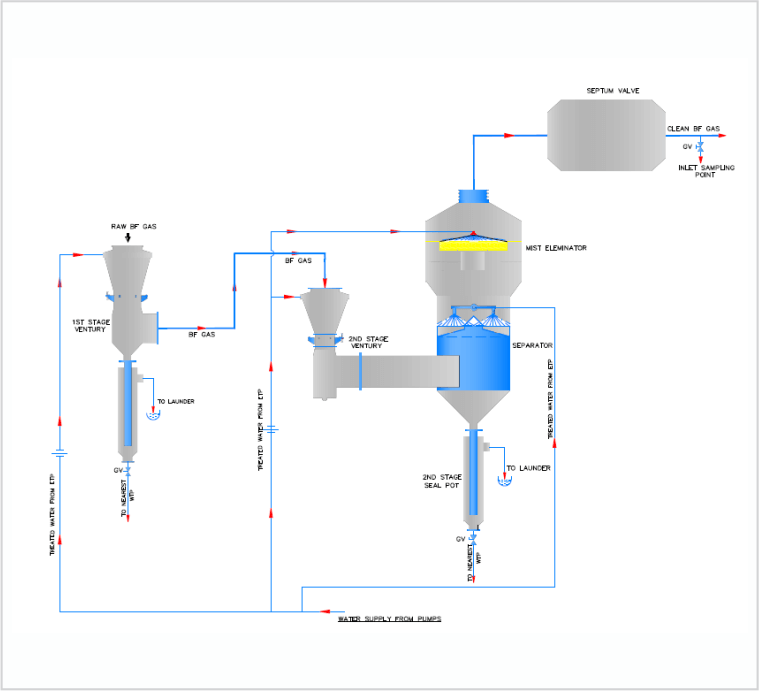

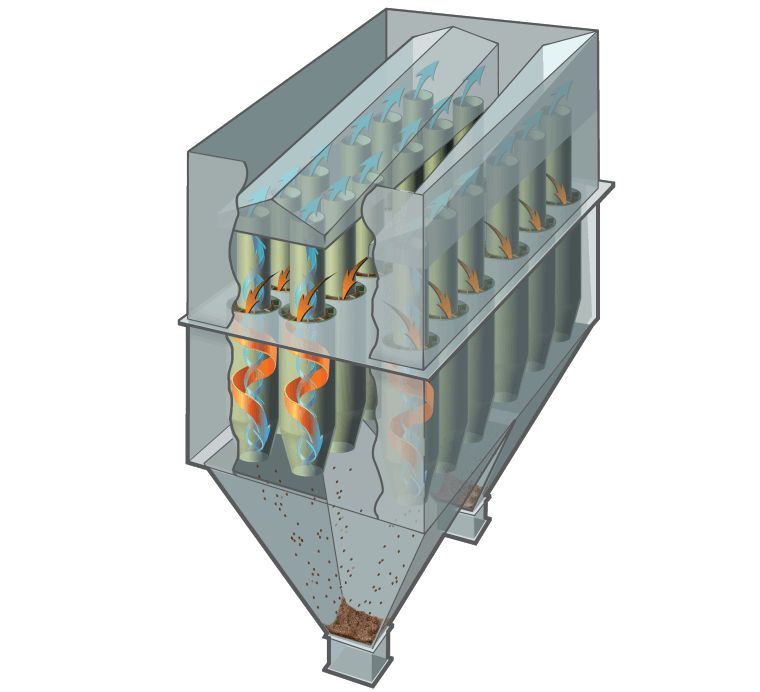

Material is transferred through tubular and inclined screw conveyor from unloading hopper to reactors with controlled transfer rate and required precision. Two sets of Triple-offset butterfly valves are provided at the discharge end of screw conveyors to ensure reactor gases does not come into contact.

System is designed with many safety features such as

- ATEX certified –As most of the powders being handled are explosive and flammable, all the electricals and instruments are ATEX certified.

- Wire mesh at Bag Unloading Hopper – This ensures that the bag is not fallen into the hopper and further to reactor.

- Copper strips for arresting static charge – To ground the static charge generated during material transfer.

- Magnetic grill – To arrest any ferrous particles or material.

- Spark proof ID fan with Aluminium impeller – Fan mounted on vent filter is designed with spark proof construction. This ensures that no sparks are generated and equipment are safe from the flammable nature of powder.

- Two stage triple Offset Butterfly Valves – To ensure that reactor gases do not come in contact with the screw feeder.

StratGem's customised solutions can cater your various requirements of any powder handling operation, providing flexibility without compromising on performance. If you have any questions, please Contact us today!

Detail Video of Reactor Powder Feeding System in Paint Industry

Simply state your requirement and solution you are looking for Stratgem will provide a solution that will suit your process needs keeping the product integrity and safe operations.

Plan to Start a Project