Investing in FGD Systems or Flue Gas Desulfurization systems: A Win-Win for Industries and the Environment

Flue Gas Desulfurization systems i.e. (FGD) play an important role in controlling air pollution by removing sulfur oxides (SOx) from flue gases produced by various industrial processes. In Pune, India, one notable Flue Gas Desulfurization system manufacturer is Stratgem. With our innovative in-house technology and extensive knowledge, we provide efficient systems and solutions for both semi-dry and wet FGD systems, playing a significant role in environmental preservation and public health.

Desulfurization, as the name suggests, involves the removal of elemental sulfur and its compounds from gas streams. Sulfur oxides, including sulfur dioxide (SO2) and sulfur trioxide (SO3), are the primary sulfur-containing air pollutants. These pollutants have hazardous effects and pose a significant concern for environmental issues. SO2, a colorless gas, can be used for various purposes when cooled and liquefied, such as refrigeration, disinfection, bleaching, or preservation. However, when released into the atmosphere, SO2 becomes a major threat.

The detrimental effects of SOx can be categorized into acid rain, health hazards, corrosion of metals, and visibility impairment. Acid rain occurs when sulfur oxides combine with atmospheric moisture, leading to the formation of sulfuric acid. This acid can damage vegetation, aquatic ecosystems, and infrastructure. Exposure to high concentrations of SOx can result in respiratory issues, cardiovascular problems, and other respiratory illnesses, causing health hazards. Furthermore, SOx emissions can corrode metals, damaging structures and equipment. High levels of sulfur oxides can also reduce visibility, leading to smog and haze.

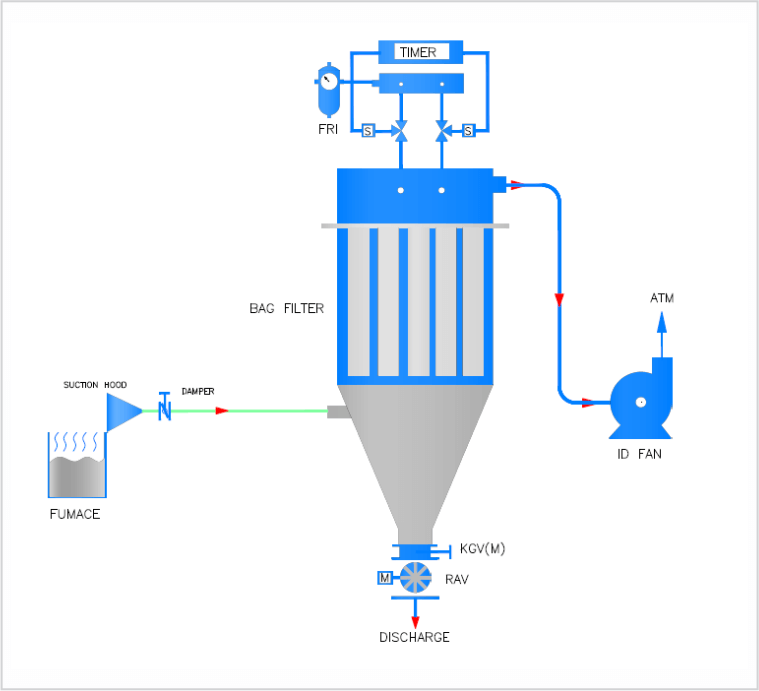

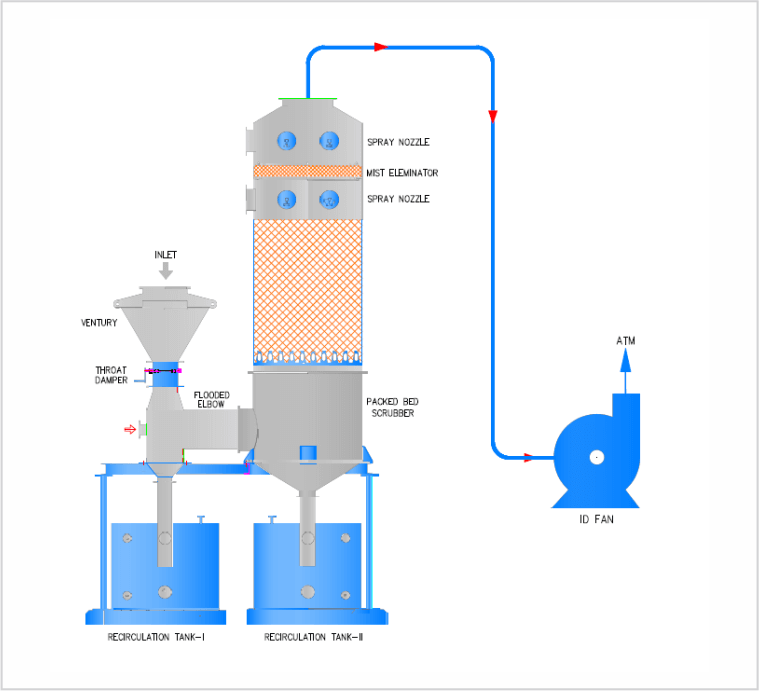

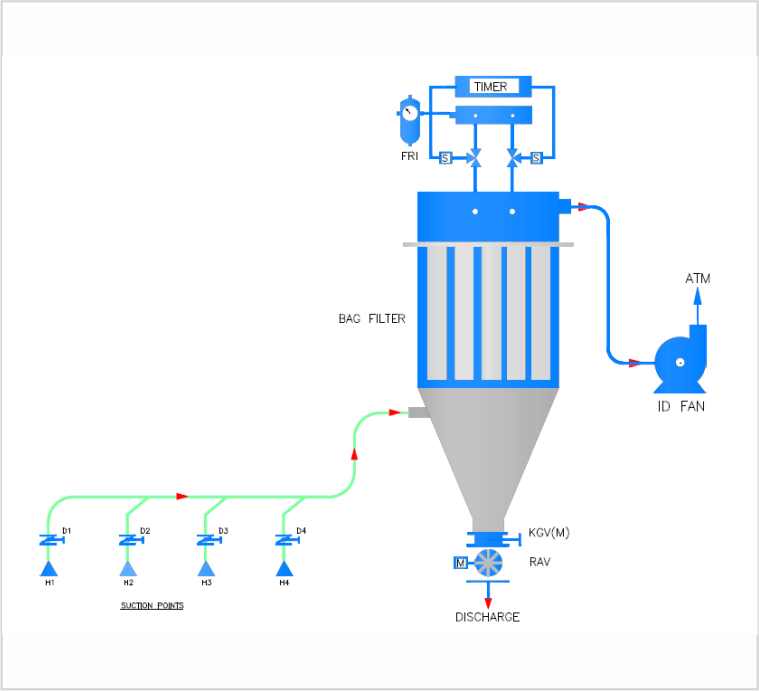

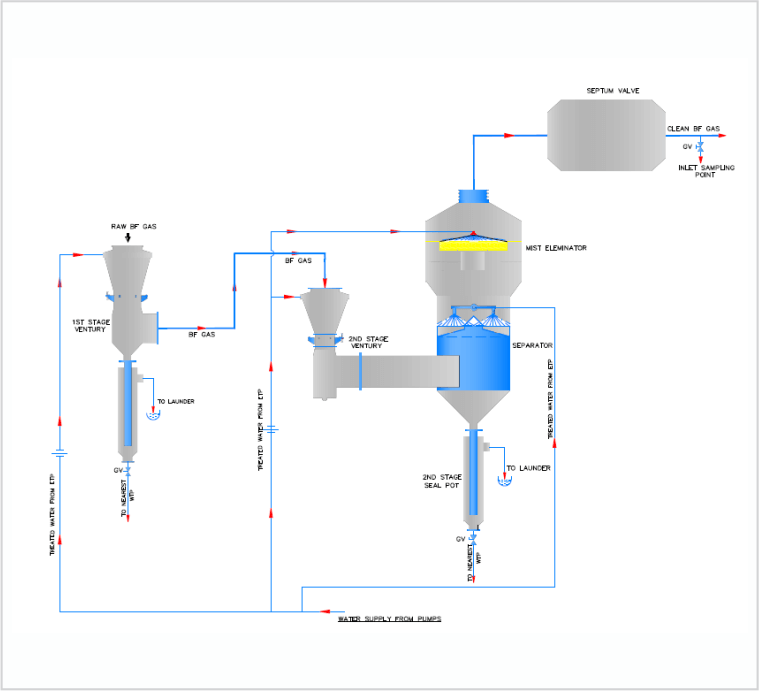

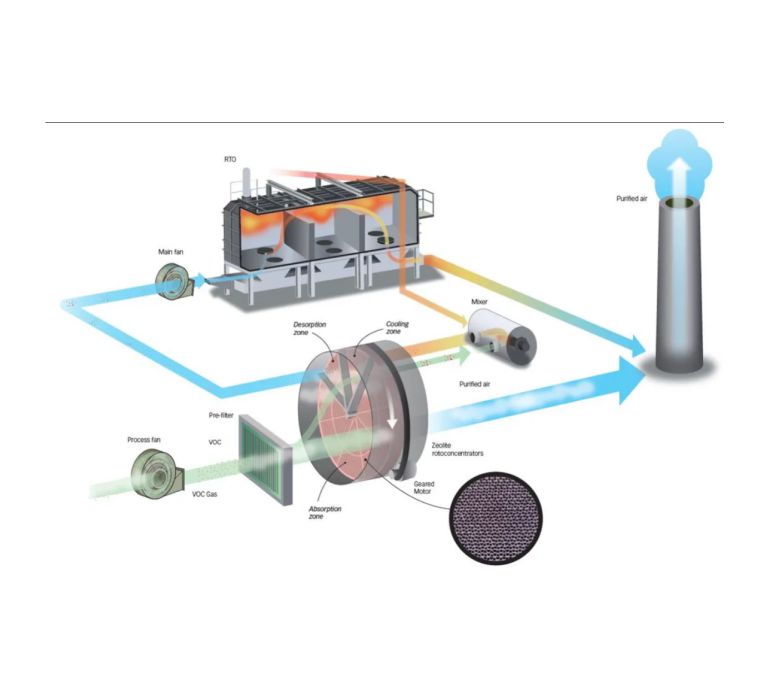

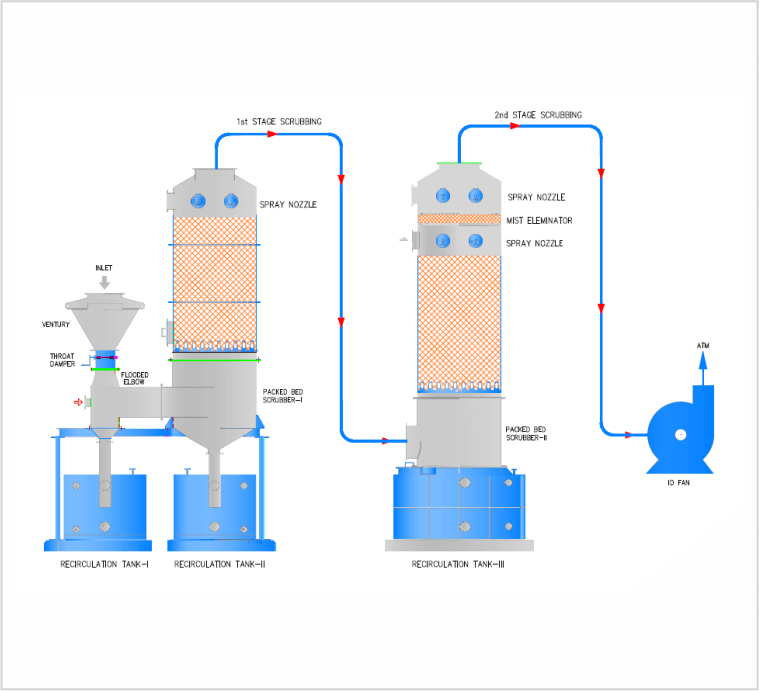

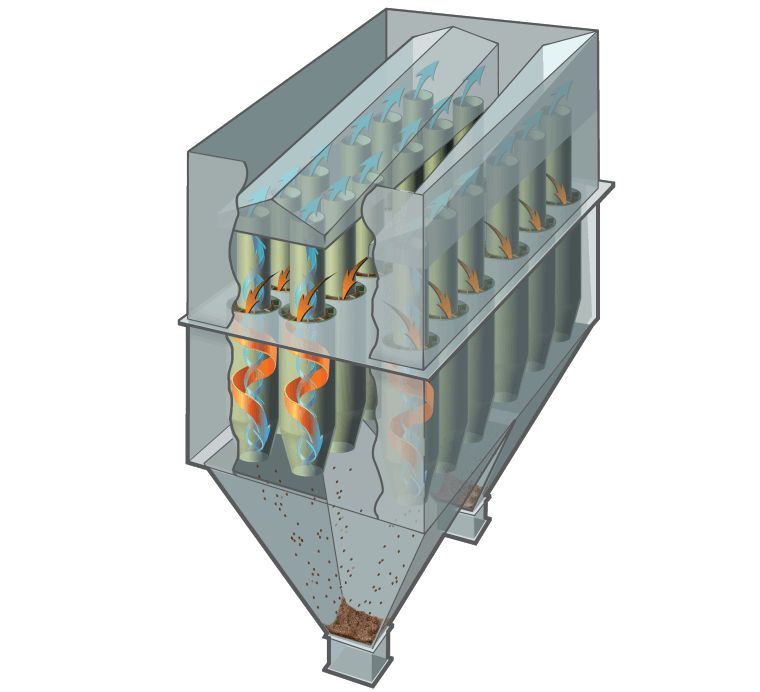

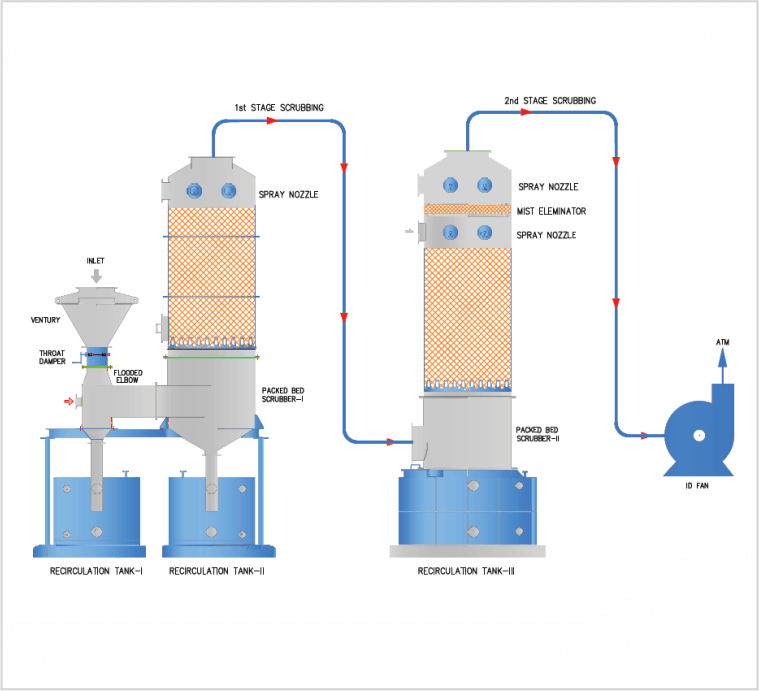

Sulphur emissions are reduced using a variety of technologies, including dry or semi-dry scrubbing systems and wet scrubbing systems. The FGD system or Flue Gas Desulfurization system consists of specialized equipment with design elements that provide a wide absorption and reaction surface area for the interaction of Sulphur compounds and alkaline reagents. Chemical reactions convert Sulphur compounds into byproducts such as gypsum.

Stratgem specializes in developing and manufacturing FGD systems that effectively reduce sulfur emissions. Our systems are meticulously designed to meet and demonstrate the required emission norms with a performance efficiency exceeding 99%. By employing their innovative in-house technology, we ensure that their Flue Gas Desulfurization system or FGD systems provide high-quality solutions to address environmental concerns associated with sulfur oxide pollution.

The applications of Flue Gas Desulfurization systems or FGD systems span various industries where sulfur emissions pose a significant concern.

Let's explore some of these industries:

- Power Generation: Fossil fuel power plants, such as coal-fired and oil-fired power plants, are major contributors to sulfur emissions. FGD systems help reduce the emissions, making power generation cleaner and more environmentally friendly.

- Oil and Gas Refining: The refining process in the oil and gas industry can release sulfur compounds into the atmosphere. Flue Gas Desulfurization systems help mitigate these emissions and minimize their environmental impact.

- Chemical Manufacturing: Chemical plants often produce sulfur-containing by-products or emit sulfur compounds during their operations. FGD systems enable the removal of these pollutants, promoting cleaner and safer chemical manufacturing processes.

- Iron and Steel Production: The iron and steel industry generates significant amounts of sulfur emissions, primarily through the combustion of fossil fuels and the use of raw materials containing sulfur. Flue Gas Desulfurization systems are instrumental in reducing these emissions and improving air quality.

- Cement Industry: Cement production involves high-temperature processes, resulting in the release of sulfur compounds. FGD systems aid in controlling sulfur emissions from cement plants, minimizing their environmental footprint.

- Waste Incineration: Incineration of waste materials can release sulfur compounds into the atmosphere. Flue Gas Desulfurization systems play a vital role in capturing and removing these pollutants, contributing to cleaner waste management practices.

- Pulp and Paper Industry: Sulfur emissions can occur during the pulp and paper manufacturing process, particularly from black liquor combustion. FGD systems help reduce these emissions, promoting sustainable practices in the industry.

Overall, Flue Gas Desulfurization system or FGD systems have versatile applications across industries where sulfur emissions pose a significant concern. By implementing these systems, industries can effectively mitigate environmental pollution, comply with regulatory standards, and contribute to a cleaner and more sustainable future.

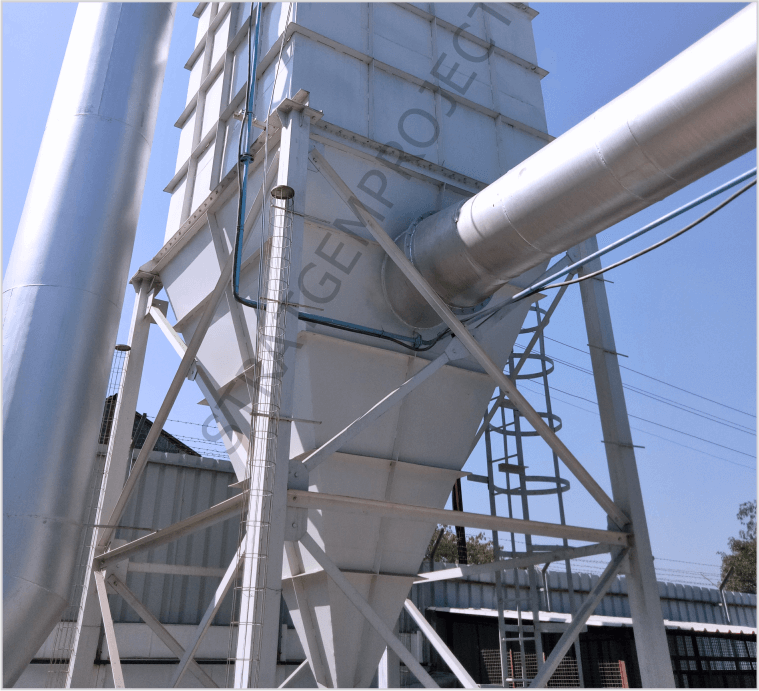

Stratgem Projects is a prominent and leading Flue Gas Desulfurization system manufacturer in Pune, India. We are dedicated to providing effective solutions for controlling air pollution caused by sulfur oxides. The Stratgem team possesses expertise in designing and manufacturing FGD systems that not only achieve but also exceed emission standards, making significant contributions to environmental preservation and public health.

With our innovative technologies and commitment to environmental sustainability, we are playing a crucial role in combating air pollution and creating a cleaner and healthier future for world. By addressing the pressing issue of sulfur oxide pollution through their efficient FGD systems, Stratgem is helping industries become more responsible stewards of the environment.

Simply state your requirements and the challenges. Stratgem will provide a solution that will suit your process needs while maintaining product integrity and safe operations.

Plan to Start a Project